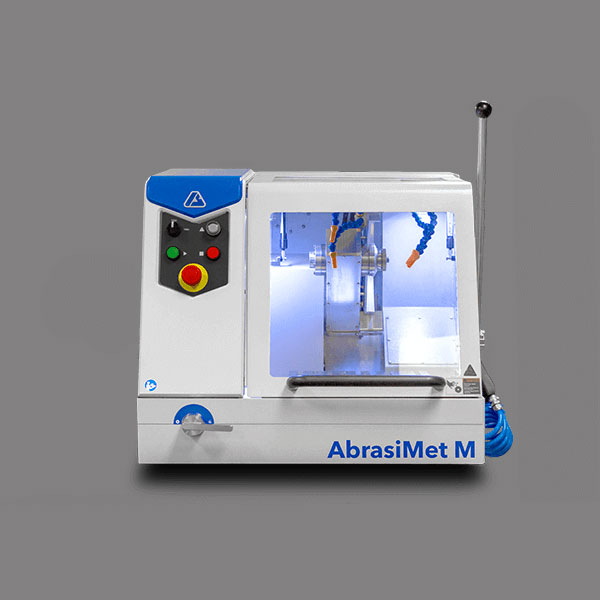

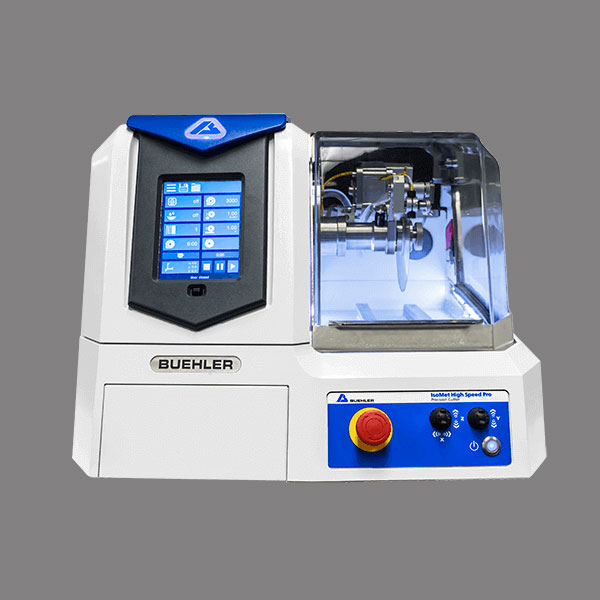

Sectioning & CuttingSimple setup and time-saving conveniences are core to Buehler’s sectioning products. Achieve high-quality cuts for any material. Buehler offers Abrasive Cutters, Precision Cutters, and a variety of metallurgical blades.

MountingGet the most from your mounting step with straightforward solutions for a variety of lab requirements. Choose from cold mounting (castable mounting) including epoxies and acrylics or hot mounting (compression mounting) including mounting presses and powders.

Castable Mounting

Our new vacuum system with unique multi-cycle capabilities, offers excellent pore impregnation in a compact format. Using your compressed air source, this system quickly and efficiently pulls a vacuum to evacuate trapped air from any porous samples, resulting in optimized edge retention and additional support for processing delicate samples.

Grinding & PolishingWhether a lab is looking to reduce rework, improve surface finish, or simplify effort for the technician, Buehler has your Grinding and polishing solution. Buehler offers grinder and polisher machines, vibratory polishers, grinding paper, and a variety of other grinding and polishing consumables.

Vibratory Polishers

The VibroMet 2 Vibratory Polisher is designed to prepare high quality polished surfaces on a wide variety of materials, including EBSD applications. The 7200 cycles per minute horizontal motion produces a very effective polishing action, providing superior results, exceptional flatness and less deformation.

EtchingBuehler Electrolytic Etching provides a consistent method to reveal microstructures after metallographic grinding

Hardness TestingBuehler Electrolytic Etching provides a consistent method to reveal microstructures after metallographic grinding.

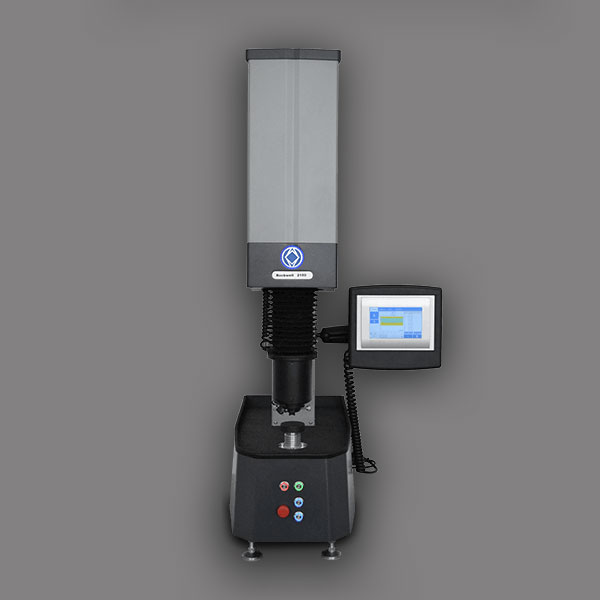

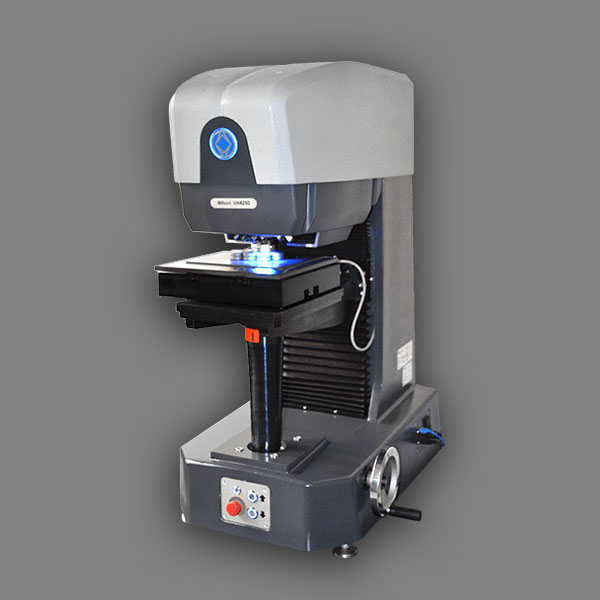

Rockwell Hardness Testers

The Rockwell 2000 Series Hardness Testers achieve the highest level of depth measurement accuracy and resolution available and as a result has the best GR&R performance in the industry. This instrument is offered in two sizes, 10 – 14 in vertical capacity, to accommodate varying sample sizes and is available in three different variations of Rockwell Regular, Superficial, or Twin hardness scales.

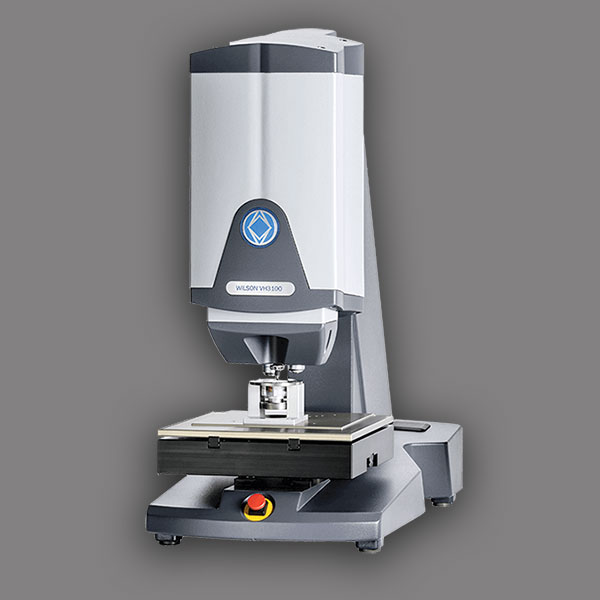

Vickers & Knoop Hardness Testers

The best pre-configured full automatic Vickers hardness tester on the market. The All-in-One Wilson VH3100 has all you need for your production control hardness testing requirements. This machine setup is configured to perform easiest operation but with advanced software solutions – DiaMet Enterprise.

Brinell & Universal Hardness Testers

The UH4000 series universal hardness tester is designed for high volume production labs and production floor. It is available in two different configurations, the UH4250 and UH4750. Universal hardness testers are designed to perform several hardness scales with one machine, in most cases for higher loads (>5kgf).

Hardness Test Blocks

Wilson Hardness test blocks set the standard for the industry and are made from the highest quality material to insure the most uniform and repeatable blocks available. A comprehensive variety of scales and blocks are available to meet the wide ranges and hardness scales associated with Rockwell®, Brinell, Knoop and Vickers testing. All Wilson test blocks are calibrated in the Wilson Hardness Calibration Laboratory in Binghamton, NY. The Wilson lab is accredited to ISO-IEC 17025 by A2LA and the testers used in the calibration process undergo a stringent monitoring process using NIST traceable devices. For the ultimate accuracy and performance in tester verification, calibration sets are available for most Rockwell scales